GRENZENLOS AUFLÖSENDUNFASSBAR MUSIKALISCH

Kompromisslos hören, Musik vollkommen erleben.

Unsere innovative High Tech Entstörung schafft ein audiophiles Erlebnis auf einzigartigem Niveau.

…ENDLICH KLINGT DASETHERNET(T)!

…ENDLICH KLINGT DASETHERNET(T)!

LAN PROTECTOR

STREAMING MEETS HIGH TECH

Analoger Klang mit digitalem Medium? Was bisher unmöglich erschien, wird nun Realität. Entstören Sie effektiv all Ihre Netzwerk- und Streaminggeräte gleichzeitig. Genießen Sie einen digitalen Klang, der Sie in ungeahnte Sphären heben wird.

WAS MACHT SCHNERZINGER SO EINZIGARTIG?

Unsere Innovationen sind High Tech in Bestform und führend im Audio- und Hifisektor.

Mit unseren Produkten erreichen Sie ein Klangniveau, das das Potential Ihrer Hifi Anlage voll ausschöpft.

Das Ergebnis: ein vollkommen realistisches und gleichzeitig puristisches Klangerlebnis, das Sie vollends begeistern wird.

NATÜRLICHE

PRÄSENZ

umfassende Signalbereinigung

EMOTIONALER

HOCHGENUSS

unfassbar pures Musikerlebnis

KRISTALLKLARE

RUHE

ungestörte Signalweiterleitung

DIE STÖRQUELLEN

Was beeinträchtigt Ihre Hifi Anlage?

Was beeinträchtigt Ihre Hifi Anlage?

DIE HERAUSFORDERUNGEN

Was stört Ihre Hifi Anlage?

Was stört Ihre Hifi Anlage?

KOMPLEX. KONSEQUENT. EINZIGARTIG.

DER SCHNERZINGER-KOSMOS

KOMPLEX. KONSEQUENT. EINZIGARTIG.

DER SCHNERZINGER-KOSMOS

PURE LEIDENSCHAFTFÜR BESTEN KLANG

PURE LEIDENSCHAFT

FÜR BESTEN KLANG

PROTECTOREN

innovative Signalentstörung auf höchstem Niveau

WLAN, DECT, Mobilfunk, elektrische Geräte, Stromleitungen etc. können das empfindliche Audiosignal stark beeinflussen.

Durch unsere zukunftsweisende GIGA CANCELING Technologie verhindern unsere Protectoren und Guards effektiv elektrische Störfelder und tragen zu einem bisher unerreichten Klangerlebnis bei.

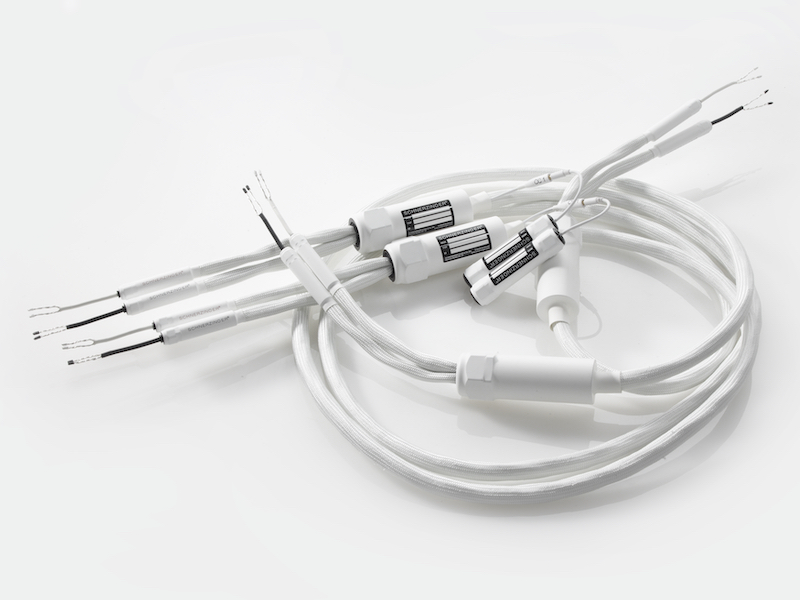

CABLE

unvergleichlich pure Signalweiterleitung

Das Geheimnis unserer Kabeltechnologie liegt im ATOMIC BONDING: zeitintensive, mehrmonatige Formatierungsprozesse erzielen eine überragende und dauerhafte Leitermaterialgüte.

In Kombination mit unserer BIDIREKTIONALEN BARRIERE erreichen wir eine unvergleichliche Reinheit in der Signalweiterleitung.

POWER

reine und ungebremste Stromverteilung

Dank des ATOMIC BONDING formatierten Leitermaterials selbst höchste Stromimpulsspitzen völlig ungebremst.

Darüber hinaus bildet jedes SCHNERZINGER POWER PRODUKT durch die BIDIREKTIONALE BARRIERE einen effizienten Schutz gegen interne und externe Störfeldübertragungen.

AUS LIEBE ZUR MUSIK.UNSERE MANUFAKTUR

Die Produktentwicklung war eine lange und leidenschaftliche Suche nach dem perfekten Klang und wie dieser entsteht.

Dabei lag der Fokus der Entwicklung stets auf der zeitrichtige und ungestörten Weiterleitung von Signalen. Und der Suche nach den absolut perfekten Bauteilen, deren gezielter technischer Optimierung sowie der idealen Zusammenstellung aller Komponenten.

Jeder Entwicklungsschritt war uns ein großer Ansporn. Denn es wurde immer wieder deutlich, wie wichtig die perfekte Güte des Leitermaterials sowie ein störungsfreies Umfeld für ein unvergleichliches Hörerlebnis ist.

UMFASSENDE PROTEKTIONUNVERGLEICHLICHE ERGEBNISSE

UNVERGLEICHLICHE ERGEBNISSE

(R)EVOLUTIONÄR. INNOVATIV. EINZIGARTIG. HIGH-TECH ENTWICKLUNGEN AUF HÖCHSTEM NIVEAU

(R)EVOLUTIONÄR. INNOVATIV. EINZIGARTIG.

HIGH-TECH ENTWICKLUNGEN AUF HÖCHSTEM NIVEAU

HIGH-TECH ENTWICKLUNGEN AUF HÖCHSTEM NIVEAU

ES RÜCKT ZUSAMMEN, WAS

ZUSAMMENGEHÖRT

ZUSAMMENGEHÖRT

ES RÜCKT ZUSAMMEN, WAS

ZUSAMMENGEHÖRT

ZUSAMMENGEHÖRT

Atomic Bonding

Das Geheimnis der SCHNERZINGER Kabeltechnologie liegt im ATOMIC BONDING. Durch diese zeitintensiven, mehrmonatigen Formatierungsprozesse wird eine überragende und dauerhafte Leitermaterialgüte erzielt, die sich in allen klangrelevanten Kriterien noch einmal deutlich selbst von den besten cryogen behandelten monokristallinen OCC Leitermaterialien abhebt.

UNSICHTBAR UND DENNOCH

KLANGBESTIMMEND

KLANGBESTIMMEND

UNSICHTBAR UND DENNOCHKLANGBESTIMMEND

Giga Canceling

Die SCHNERZINGER GIGA CANCELING Anwendung ist eine zukunftsweisende Technologie, die elektrische Ströme bis in den dreistelligen Giga-Bereich in Hochgeschwindigkeit verarbeitet. Dabei wird ein Entstörsignal generiert, welches das Umfeld mittels wissenschaftlich anerkannter Physik effektiv vor Klangbeeinträchtigungen durch elektrische Störfelder schützt.

KLARE TRENNUNGBESTE ENTSTÖRUNG

KLARE TRENNUNGBESTE ENTSTÖRUNG

Bidirektionale Barriere

SCHNERZINGER KABEL und POWER Produkte arbeiten konstruktionsbedingt mit einer BIDIREKTIONALEN BARRIERE, welches über Stromnetz, Kabel und Komponenten einstrahlende Störfelder blockiert bzw. ableitet. Die Effektivität der BIDIREKTIONALEN BARRIERE kann in kritischen Umgebungen durch optionales Zubehör weiter verstärkt werden.

Pressestimmen